From component and sub-assembly testing to full vehicle testing

Automotive testing has always been critical – not just to get the initial design right but every component and assembly rolling off the production line thereafter. Now the pressures are greater than ever as the industry seeks to improve its environmental performance and looks to transition to hybrid and full electric cars – not just incremental changes but huge leaps in automotive evolution.

Confidence in the safety and performance of these cars – both those being produced and developed – can only come from test procedures that are appropriate, accurate and dependable. This is where Unitemp’s test cabinets play a crucial role.

- Engine testing

- Component and sub-assembly testing

- Full vehicle testing

- Secondary battery testing

Testing for Real Life Situations

Environmental test chambers allow real-life temperature and humidity conditions to be replicated as the object under test goes through rigorous testing procedures. Particularly when developing new battery chemistries with unknown behaviour, safety of test engineers is of equal importance to the safety of the end product, so robust test chambers are critical.

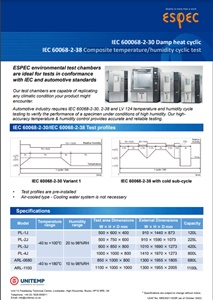

At Unitemp, we provide the highest quality equipment from Espec for a range of needs including engine testing, component and sub-assembly testing, full vehicle testing, and secondary battery testing. Espec’s standard and custom-engineered environmental chambers and automotive test equipment is capable of replicating any climatic condition your product might encounter.

Espec’s Automotive Environmental Chambers provide precise environmental conditions for all environmental simulation-based testing and research applications. Each chamber is equipped with the most accurate sensors, the latest controls and data acquisition systems, and is fully automated via a Programmable Logic Controller (PLC) or PC. The PLC controls the automotive environmental chamber and can be supplied with data acquisition and storage via a user-friendly, Windows-based computer system.

Having proven test chambers with this level of automation and control allows manufacturers to confidently adhere to company and industry standards. Espec’s history and expertise in this field ensures our test solutions are designed to meet the specific needs of the automotive industry, from component test chambers right up to drive in test chambers for full vehicle testing.

Datasheet – LV 124 Standards. Condensation test of automotive components.

Environmental Test Chambers for The Automotive Industry

Benchtop SH-SU Chambers

Reach-In Platinous Chambers

Reach-In AR Series

Industrial Ovens

Video

Testing for innovative storage solutions

Support when you need it

from expert people

Our after sales service and ability to support existing installations, from planned maintenance schedules and emergency repairs to full on-site refurbishment mean our customers equipment retains optimal performance and up time.