Environmental Chambers for Solar Panel Testing

Our chambers are solid, one-piece construction, using fibreglass insulation and an angle-iron frame. The stainless steel interior liner is reinforced and continuously welded, including leak-testing for integrity.

The angle-iron frame provides enough structural strength to allow a full-opening door for easy loading of large arrays without restriction. A full-opening door can also allow floor-space saving over panel chambers.

Our chambers are compliant for the following test methods:

Thermal Cycle Test

Requires temperature cycling between 85°C and -40°C, 50 or 200 times

Humidity Freeze Test

Cycling between hot/humid 85°C/85%rh and subfreezing -40°C ten times, with extended soaks at 85/85

Damp Heat Test

A long term, 1,000 hours, test at 85°C/85%

ESPEC chamber for Damp Heat Testing only is also available.

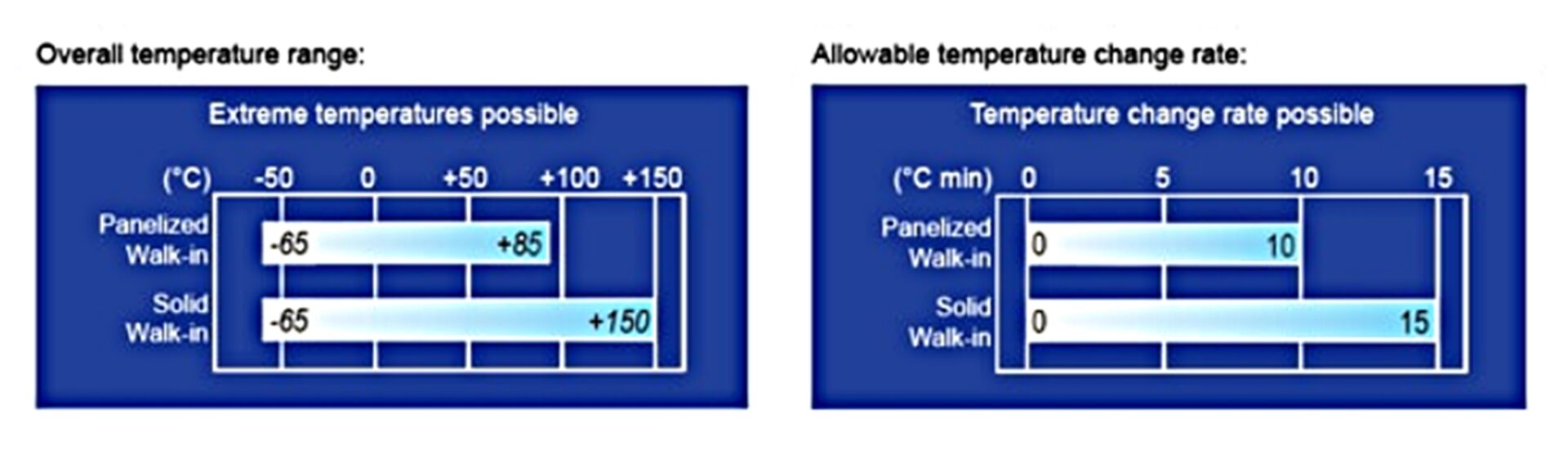

Comparison with conventional chambers

Our conventional chambers, are built using panels with foam insulation that cannot withstand higher temperatures and are more susceptible to leaks at the seams under extreme conditions, such as fast temperature cycling.

Note: Actual change rate capability is determined by selection of heating/cooling system based on your requirement.

Easy to use Programmer

The ESPEC P-300 controller has USB and Ethernet features to make programming and data collection easier than before. The user interface uses tabs for faster access to any screen. Standard USB and optional Web Controller/Ethernet interfaces make programming and data acquisition much simpler. In addition, improved algorithms make operation faster and smoother.

Features

Cabinet

- Solid-construction chamber is a one-piece welded structure with six inches of fiberglass insulation and a 304 stainless steel interior

- Full-opening door(s) with heated windows

- One 4″ (100mm) diameter cable port with silicone plug

System Controls

- Instrumentation console mounted to the right of the chamber door

- Three levels of overheat protection including an independent, adjustable sensor

- ESPEC’s Exclusive SCP-220 Programmer

Optional Capabilities

- IR Infrared Lighting for radiant surface heating of samples

- Solar simulation lighting per DIN 75-220

- Integration with vibration shaker systems

Refrigeration and Plenum

- Modular or Integrated Air Plenum with cooling coil, wire heaters, and two circulator blowers

- Non-CFC refrigeration system using Copeland Discus or Scroll compressors

- Automatic water regulator controls water usage on water cooled models

- Humidity system includes steam generator and dehumidification coil

- Instrumentation console mounted to the right of the chamber door

- Three levels of overheat protection including an independent, adjustable sensor

- ESPEC’s Exclusive P-300 Programmer

- IR Infrared Lighting for radiant surface heating of samples

- Solar simulation lighting per DIN 75-220

- Integration with vibration shaker systems

Related Products

- Don’t need to go above 85°C? Prefer a chamber than can be assembled in pieces? See Panelized Walk-in Chambers

- Need solid construction style, but not walk-in size? See AGREE Vibration-compatible chambers

VideoWalk-in Temperature (& Humidity) Chamber

Support when you need it

from expert people

Our after sales service and ability to support existing installations, from planned maintenance schedules and emergency repairs to full on-site refurbishment mean our customers equipment retains optimal performance and up time.